Aluminum Windows: The Ultimate Guide to Alloy and Hurricane-Resistant Options

Introduction Aluminum windows have become one of the most popular choices in modern construction, offering a balance of strength, style, and practical...

Read MoreContent

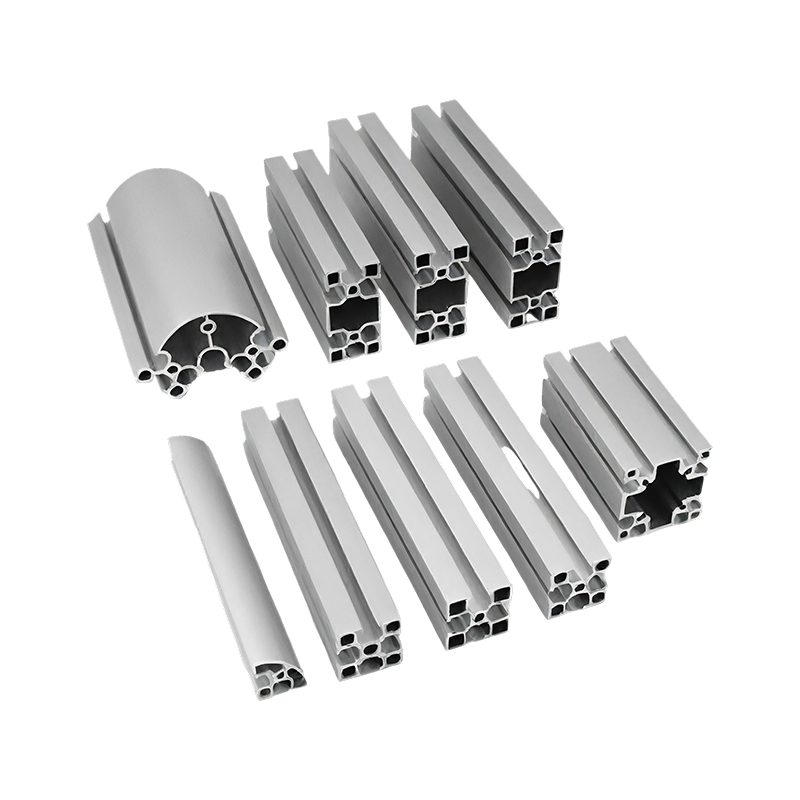

Aluminum profiles have become a key component in modern architecture due to their light weight, high strength, and excellent corrosion resistance. They are widely used in curtain walls, window and door frames, and facade structures. The smooth surface and anodized or powder-coated finishes provide a modern aesthetic that aligns with contemporary building designs. In addition, aluminum profiles can be easily formed into complex shapes, making them ideal for customized structural and decorative elements.

In industrial manufacturing, aluminum profiles are used in machine frames, conveyor systems, and equipment housing. Their combination of strength and lightness allows for robust yet easily adjustable modular systems. Aluminum’s non-magnetic and corrosion-resistant properties make it suitable for cleanroom environments, automation lines, and precision assembly platforms. Engineers prefer aluminum profiles for their ability to maintain dimensional stability and facilitate rapid prototyping.

The solar energy industry relies heavily on aluminum profiles for panel frames and mounting systems. These profiles offer excellent resistance to UV exposure and outdoor weathering, ensuring long-term structural integrity. The lightweight nature of aluminum reduces transportation and installation costs while maintaining high rigidity to support photovoltaic modules. Its recyclability also aligns with the environmental sustainability goals of renewable energy projects.

Aluminum profiles are increasingly used in furniture manufacturing, especially in office partitions, display racks, and modern home furnishings. Their clean lines and metallic texture fit the minimalist style trend. Manufacturers value aluminum profiles for their easy processing and ability to integrate with materials such as glass, wood, and plastic. The use of anodized aluminum enhances both appearance and durability, preventing surface wear and oxidation.

One of the key advantages of aluminum profiles lies in their flexibility for customization. Manufacturers can adjust alloy composition, wall thickness, and surface treatments to meet the performance and aesthetic needs of specific projects. Common customization options include:

| Application Area | Function of Aluminum Profile | Key Advantage |

| Architecture | Curtain walls, window frames, facades | Corrosion resistance, modern aesthetic |

| Industrial Manufacturing | Machine frames, conveyors, enclosures | Lightweight, easy assembly |

| Solar Energy | Mounting systems, panel frames | Weatherproof, sustainable material |

| Furniture Design | Partitions, racks, decorative frames | Elegant finish, easy customization |

Aluminum profiles contribute to sustainable construction and manufacturing due to their recyclability and energy-efficient production. Recycled aluminum retains the same physical properties as primary aluminum, reducing carbon emissions significantly. Moreover, the long service life and minimal maintenance requirements make aluminum profiles a cost-effective choice for long-term projects.